I can still picture India’s early telephone days. My family had to wait ten years for a connection and pay a fortune to utilise it. I wouldn’t have believed you if you had told me back then that almost everyone in India would have a mobile phone—some even getting numerous connections in the same phone. Yet here we are, with tens of millions of contract workers relying on their mobile phones as their primary source of income. A hurdle to using Google maps and GPS is just not literacy.

For this generation, I think 3D printing will be an equally transformational technology.

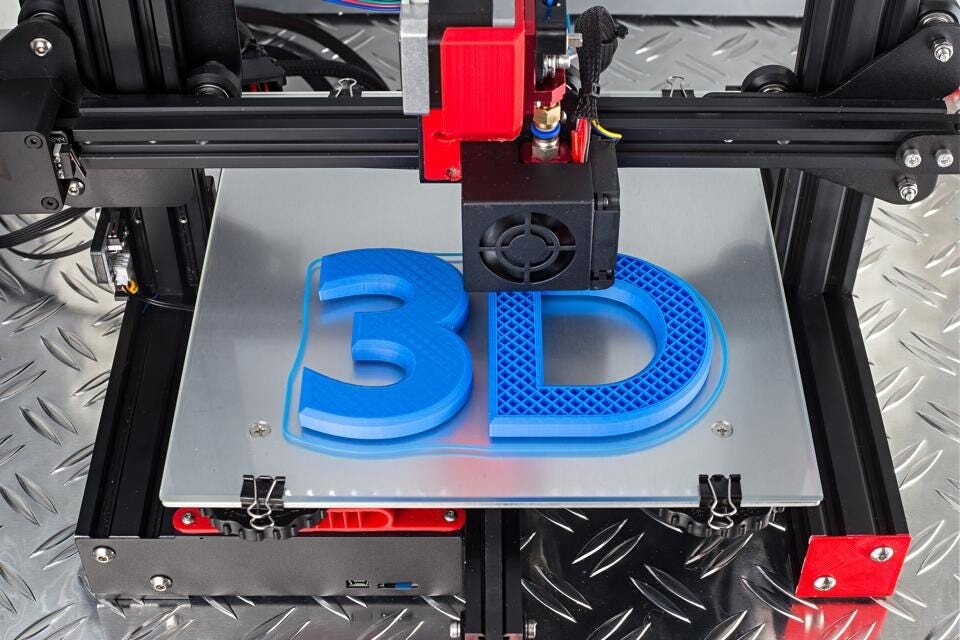

For those who don’t know, 3D printing is an automated method for creating three-dimensional objects out of materials including thermoplastics, liquids, resin, and, more recently, metals like gold, silver, titanium, and ceramics. 3D printing deposits material layer by layer to produce precise shapes, straight out of science fiction.

As a quick prototyping process, it gained popularity in the 1980s. A 3D printer would be used to give a concept physical form so it could be plainly displayed. What’s more, it significantly shortened the period from idea to prototype to only a few days.

But there was little widespread use of 3D printing. mostly due to two factors: capabilities and cost. Most 3D printers can only really produce straightforward items in limited sizes and using specialised materials. In the 1980s, a 3D printer would have cost roughly $350,000 (almost $700,000 now). Although capabilities remained limited and pricing remained prohibitive for individual users, technology evolved tremendously over time.

Only in the past five years has 3D printing gained popularity. The capabilities have substantially increased. 3D printing is being used by the manufacturing sector to produce spare parts, test the application, and launch goods more quickly. NASA is creating rocket engine injectors and sending a 3D printer, or “small factory,” into space so that astronauts may make tools.

The number of 3D printed prosthesis is rising. Human organs are being 3D printed by Dr. Anthony Atala’s group at the Wake Forest Institute for Regenerative Medicine. General Motors soon shifted to producing ventilators and personal protection equipment by using its 3D printing capabilities.

But the price issues continue. Up until now, 3D printing has been the specialty of big businesses or well-funded colleges. Certainly not the average person. This is due to:

- The market’s inexpensive $200 3D printers offer relatively little capability. Even a few simple toys are difficult to print.

- It is currently not user-friendly for everyone and requires some CAD knowledge.

- It also requires the rare skill to construct 3D printable structures.

- The same as any conventional sheet of paper we’d put in a typical printer, raw materials are not always simple to get by.

- Consumer 3D printers can also be a bit fussy and challenging to fix.

These, in my opinion, are just the high-potential technology sector’s normal growing pains. It won’t be long before we can print anything we need by simply clicking on a mobile app. You could print a three-dimensional version of a photograph you downloaded from the internet, for example.

Similar to the SaaS model for software products, there may come a time when we may purchase the design for an item we need and have it printed in our homes, such as a coffee cup, clock, or pen. Additionally, this would address the instant gratification issue that e-commerce hasn’t been able to address.

In my opinion, 3D printing is the solution to mass personalization. Businesses can offer limitless customization options to customers for modular designs. For instance, if you 3D print your computer, you can alter the various components to make something specifically tailored to your need. If produced in the conventional manner, a product with this level of personalization would be quite expensive. A 3D printer alters that.

It profoundly modifies the production economics. The economies of scale, which dominated industry throughout the 20th century, will no longer be a barrier. Any product can be produced in a single unit at a reasonable cost.

Similar to how e-commerce handled the long tail issue by making uncommon goods accessible to customers, 3D printing can drive the next stage of production. In fact, it could alter the manufacturing sector as a whole.

It might lead to the development of numerous distributed cottage companies producing goods for the neighbourhood. For instance, the gourmet food business, particularly chocolatiers, is very interested in 3D printing. This could increase the demand for personalised chocolate.

It could lessen the need for international shipping and transit of goods, reducing carbon footprint. Tvasta is a 3D printing solution for the housing and construction industries, developed by a business incubated at IIT-M and L&T Construction.

Even the process of bringing new products to market might be made exceedingly simple for inventors using 3D printing. Due of its accuracy and originality, 3D printed jewellery is becoming more and more popular.

Over $600 million has been invested globally in at least 45 3D printing firms. Desktop Metals and Carbon have attained unicorn status. The market for 3D printers in India is expected to reach $79 million this year and is expanding.

HAL and Wipro 3D signed an MOU for the production of aeronautical components last year. Personal protection gear is available from Imaginarium, Divide By Zero, and Anatomiz3D in 3D printed form.

3D printing is more advanced now. It isn’t a science fiction or fantasy anymore. It would be so ingrained in our life in twenty years that we may not think about it anymore.

Transformative technologies have appeared in every generation, changing how people live. These innovations, which ranged from the radio to telephones, computers, the internet, and more, altered the very fabric of society.

For this generation, I think 3D printing will be a similarly transformational technology.

The method of creating three-dimensional objects utilising thermoplastics, liquids, resin, and, more recently, gold, silver, titanium, and ceramics, is known as 3D printing. 3D printing deposits material layer by layer to produce precise shapes, straight out of science fiction.

Potential benefits of 3D printing include: enabling large-scale product customization.

give rise to several spread cottage firms that produce goods for neighbourhood populations

Reduce the requirement for international shipping and transportation of goods to reduce carbon footprint.

Make launching new items into the market for entrepreneurs exceedingly straightforward.

3D printing is more advanced now. It isn’t a science fiction or fantasy anymore. It would be so ingrained in our life in twenty years that we may never think about it anymore.

Written by: Futuristic Frog